e

Evaluate your garage floor

Epoxy is a tough, long-lasting coating that you paint onto the concrete. It resists grease, oil and many other substances that would ruin ordinary paint. It cleans easily and can be found in a variety of colors (if you look hard enough), so you can keep your garage floor sparkling clean and attractive for years.

However, the reality of this challenging project is, one, not all concrete floors will hold a coating, and two, preparing concrete can be labor intensive and tedious. That said, this story will help you assess your concrete’s condition, show you how to clean and etch it, and demonstrate how to apply an epoxy surface that will handle car traffic, chemicals, oils, salt and scraping better than any other paint or stain.

As with any other paint job, success lies in the prep work. Plan to spend the first day removing oil spots, cleaning/degreasing the floor, etching it with a mild acid, and scrubbing, vacuuming and rinsing (a lot!). Day two is for filling cracks and applying the first coat of epoxy, which is followed by a second coat on day three. This job doesn't require many special tools. But to do the best job (and save your back), we recommend that you rent a walk-behind power floor scrubber (Photo 2) with a stiff brush attachment. Brushes work better than scrubbing pads on concrete, but buy two pads if a brush isn't available. Also, rent a wet vacuum if you don't own or have access to one.

Test Your Concrete for Moisture

Lift the corner of a plastic bag that's been taped to the garage floor for 24 hours. If it's dry underneath, you can proceed with an epoxy coating. If you see moisture under the plastic, don't coat the floor with epoxy; water pressure will break the bond.

Analyze the floor and weather

Before you even consider epoxy paint for your floor, test to determine if dampness is coming up through the concrete from the ground. If moisture is evident, your floor isn't suitable for epoxy. Also, forgo the project if a concrete sealer was previously used (you'll know a sealer has been used if water beads up when applied to the surface). If you're dealing with a new slab, you must wait a minimum of 28 days, preferably two months, for the floor to cure and dry thoroughly before applying a garage floor coating. And if you're dealing with a previously painted floor, the best advice is to remove the paint, especially when you're applying a solvent-based epoxy that could soften any that remains.

If your concrete passed these tests, make sure the weekend weather passes too. The temperature of the concrete must be a minimum of 55 degrees F, with an air temperature between 60 and 90 degrees for optimum epoxy curing/drying.

Floor cleaning

Photo 2: Use an electric floor scrubber

Wet the entire floor with a hose, then scrub back and forth using an electric floor scrubber with a brush attachment (or a coarse scrubbing pad if a brush attachment is unavailable). Pour cleaner/degreaser mixture onto the floor as you go to keep suds

To begin, use a flat-edged shovel or scraper to loosen hardened surface debris, then sweep it out with a stiff-bristle garage broom.

Next, mix up a 5-gallon batch of water and concrete cleaner/degreaser according to label directions (found at home centers and hardware stores).

Once spots are cleaned, power-scrub the entire floor (Photo 2). To clean a two-car garage floor, plan on scrubbing for 20 to 30 minutes (keep the floor wet at all times). Make sure you scrub with a stiff-bristle hand brush along the walls and in the corners where the machine cannot reach. Once you're satisfied with dirt removal, vacuum up the cleaner for proper disposal (Photo 3). Don't just wash the product down the drive into the storm sewer. The environmental effects of cleaning products can vary widely. Check the product label or call the manufacturer for the proper waste disposal method. We looked up the Material Safety Data Sheet for the product we used (made by Behr) on the Web site www.msdssearch.com and learned we could pour the waste into the “sanitary sewer” (toilet). Also check the label or call the manufacturer for instructions on safe disposal of all leftover product and containers. When in doubt, call your city or county environmental office.

Etch the concrete with muriatic acid

Photo 5: Power scrub the floor again

Power-scrub the 10 x 10-ft. area for 5 to 10 minutes. Repeat sprinkling/ scrubbing for each 100-sq.-ft. section, making sure the entire floor stays wet. When you're done, spray a large volume of water on the floor to flush the residue out. Power scrub again, then rinse two or three times. Let the floor dry overnight, until it appears white.

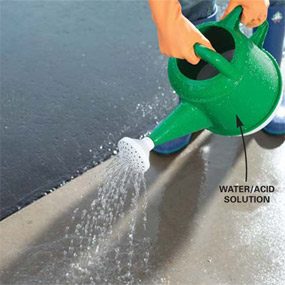

Before etching concrete with the acid solution (Photo 4), hose down your entire driveway and several feet beyond the sides of the drive. This aids in the final rinse out of the garage so the material will flow more easily down the driveway. Now sprinkle the 10:1 ratio of water to muriatic acid mixture and power-scrub the floor (with a rinsed brush attachment or new pad; Photos 4 and 5).

When you're finished, take your hose and nozzle end and flood the floor with water, spraying the material out of the garage for a good 10 minutes (diluted muriatic acid can be rinsed with large volumes of water into a storm sewer, according to the manufacturer). Rinse off the power scrubber brush/pad, then scrub the wet floor one last time for 5 to 10 minutes.

Finally, rinse out the entire floor and driveway two to three more times. The concrete surface should now feel like fine-grit sandpaper. If not, you need to repeat the acid washing. Finally, to speed the drying process, squeegee out any remaining pooled water, and take a rag and dry any remaining spots, cracks or chipped areas. Leave the garage door open overnight to speed drying.

CAUTION!

Always add acid to water, not water to acid and wear an organic vapor/acid respirator (Photo 7).

Choosing an epoxy

The final critical decision is what type of epoxy to use. Epoxy floor paints are tough resins that come in two separate parts that you mix together just before you apply them. You can divide them roughly into three types: 100 percent solids, solvent based and water based.

The 100 percent solid type is almost pure epoxy; it doesn't contain solvents that evaporate. These products are expensive and difficult to handle because they harden so rapidly. They're best left to the pros.

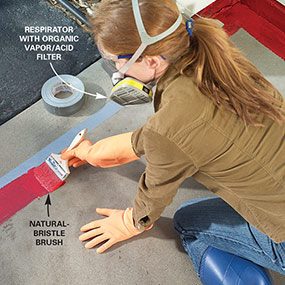

The solvent-based epoxies typically contain from 40 to 60 percent solids (epoxy). They penetrate and adhere well and are the choice of most pros. And they're often available in a wide range of colors, which is one reason we chose this type for our demonstration. But they do have some drawbacks. The solvents are powerful and potentially hazardous; you MUST use a respirator (a 3M 5000 series respirator with an organic vapor/acid gas filter, or the equivalent in another brand). The respirator must fit tightly to your face so you don't breathe the fumes. In addition, you must ventilate the garage well and keep other people away from the odors.

Solvent-based epoxies also may be harder to find. Some paint specialty stores may carry them (Sherwin- Williams and ICI Dulux, among others), but otherwise you'll have to go to an industrial supply–type store. Check the Yellow Pages under “Paint, Wholesale & Manufacturers” or “Industrial Equipment & Supplies, ” or look online.

The water-based epoxies also have two parts that you mix just before application. And they also typically contain 40 to 60 percent solids. The benefit of this type of epoxy is that there are no hazardous solvent fumes. And at least one brand, Rust-Oleum's EpoxyShield Garage Floor Coating, is widely available at home centers.

Whether you're working with solvent- or water-based epoxy, we recommend that you apply two coats to get enough build for long-term wear and durability. “Build” refers to the thickness of the dried epoxy film. Typically, an epoxy with a higher solid content will give a higher build. And, in general, prices tend to reflect the amount of epoxy in the mix—the more epoxy, the higher the build and the higher the price.

For a two-car garage (450 sq. ft.), you'll need 2 to 3 gallons per coat (depending on the percent of solids in the epoxy you buy—read the container). Check the cans for coverage to make sure you buy enough.

CAUTION!

Wear appropriate gloves, eye and lung protection, and rubber boots, according to the product labels. Turn off gas to the water heater or any other appliance located in the garage. And take precautions to keep children and pets away from the garage and driveway.

Patch the cracks

First thing in the morning, after the floor has dried overnight, fill 1/4-in. cracks and larger, plus holes or spalled areas, with an epoxy crack filler, available at home centers. Use a plastic putty knife to scrape the surface level and smooth. Let this dry for four hours (check label directions) before you begin painting your first coat of epoxy.

First coat of epoxy

Photo 7: Brush on epoxy around the perimeter

Tape the area directly underneath the garage door with duct or masking tape, then brush a 4-in. strip of epoxy along the walls and against the tape.

Photo 8: Load the roller

Dip a 9-in. wide, 3/16-in. short-nap epoxy roller into the bucket so only the bottom half of the roller is covered. (This helps keep epoxy out of the roller.)

Photo 9: Roll on the epoxy

Paint a big wet “W” pattern that's about 3 to 4 ft. square, then backroll to fill in the pattern—all in 60 seconds. Finish by going over it lightly to remove roller marks.

Mix the correct amount of epoxy (Photo 6) to cover the square footage of your garage floor according to label directions. It's critical that you allow the mixed product to stand undisturbed for the specified time on the label before applying it. You also must apply the entire batch you mixed up before the specified time expires. We used a 40 percent solid, solvent-based epoxy from a local industrial supplier/manufacturer that had to sit for 30 minutes, and the batch had to be used up within 24 hours (and it was offered in almost 20 colors).

While waiting for the crack filler to cure, use a high-quality natural-bristle paint brush and cut in the floor edges (Photo 7). Also, tape the area directly underneath the garage door with masking or duct tape, allowing you to shut the door overnight. This is intended to keep out dust, dirt, pets and children until the floor is dry. And put a “Do Not Enter” sign along with tape across the doorway leading to the garage from the house.

Coating the floor

If you move at a steady pace (Photo 9), you should finish your two-car garage floor in less than one hour. (Remember not to paint yourself into a corner!) The solvent odors are powerful. Be sure to wear a respirator (Photo 7) and keep the garage door open at least an hour after coating.

Tips:

Keep a clean cotton rag handy and some Xylol epoxy thinner (for solvent-based epoxy) to clean up epoxy drips and spills.

Consider adding epoxy paint to the bottom 4 in. of drywall, wood or concrete wall along the floor to protect it when you hose the floor clean in the future.

Second coat

Let the first coat dry overnight, for a minimum of 16 hours (or according to label directions, since epoxy products vary). Add a non-skid product to the epoxy (Photo 10) for the second coat, especially if your vehicles drag snow and moisture into the garage, or you'd feel safer on a less slippery floor. Repeat the “cutting in” and floor painting like the day before (Photos 7 – 9).

Wait another 16 hours (check label directions) after finishing before allowing foot traffic. You can start parking your cars on the floor after approximately three to seven days (depending on the epoxy label directions). A full cure for the floor takes approximately one month.

Tip:

A coat of floor wax applied over the top of a cured epoxy floor will make it easier to clean.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Wet/Dry Shop Vacuum

- Paintbrush

- Paint roller

- Wheelbarrow

Power floor scrubber (rental), stiff bristle brush, organic vapor/acid respirator, rubber boots, rubber gloves, safety glasses.

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here's a list.

- Cleaner/degreaser fluid

- Muriatic acid

- Epoxy crack filler

- Epoxy floor paint

Shopping List

source:- http://www.familyhandyman.com/garage/how-to-apply-epoxy-floor-paint-to-your-garage/view-all

Thank you for sharing your thoughts and knowledge on this topic. This is really helpful and informative, as this gave me more insight to create more ideas and solutions for my plan. I would love to see more updates from you.

ReplyDeleteElcometer 500

Thank you, for providing this informative and comprehensive blog. This is very interesting Blog.

ReplyDeletePainting Contractors Perth | Epoxy Floor Painting Perth

Nowadays, with the increase in advancement of technology more number of customers started installing garage floor coatings for their garage.

ReplyDeleteflake garage floor coating New York